Blog

Lead Solder vs. Lead-Free Solder in PCB Manufacturing

Solder is the glue that holds a PCB together, and without it, there would be no connections between PCB components. But there is much more to solder than heating it up and spreading it around. The key to a successful PCB project is understanding the advantages and disadvantages of the two most common solder types — lead and lead-free.

A Guide to PCB Corrosion

Corrosion on printed circuit boards (PCBs) is a major problem, leading to malfunctioning and component damage. Knowing what causes corrosion, how to identify it, and steps for prevention can help avoid costly repairs and ensure long-term board performance. With proper preventive measures and reputable PCB manufacturers, you can extend the life of your board and protect it from the damaging effects of corrosion.

What Are the Different Types of PCB Surface Finishes?

A final step in the PCB fabrication process, the decision to use a specific finish type is often driven by cost, electrical properties, durability, and other factors. Common PCB finishes include HASL (hot air solder leveling), OSP (organic solderability preservatives), and ENIG (electroless nickel immersion gold). When selecting a surface finish, it’s essential to consider the benefits and drawbacks of each for successful performance for any electronics product.

How to Prevent Solder Balls on PCB

You must take precautionary measures before, during, and after production to prevent solder balls in printed circuit boards. Solder balls on PCB components are a recipe for disaster, so understanding the primary underlying causes and how to avoid them is vital. But you can prevent the formation of solder balls with the right tools, techniques, and precautions, ensuring optimal and lasting function. By partnering with a reputable PCB manufacturer, you can rest assured that your boards will be free of solder ball errors.

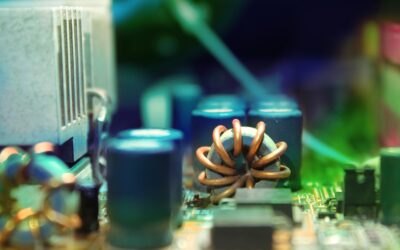

What Are the Different PCB Heat Dissipation Techniques?

Most PCB designs can’t handle operating temperatures above 80°C. After this temperature, the board material becomes fragile and prone to breakage. A careful study of PCB heat dissipation techniques can help designers ensure that their PCBs can safely operate at higher temperatures without compromising reliability.

Comparing Offshore vs USA PCB Manufacturer

There are advantages and disadvantages to choosing offshore or USA PCB manufacturers. Electronics enterprises must consider several factors to ensure quality products, excellent customer service, and cost-effective production. Understanding the challenges and benefits of working with an offshore or USA PCB manufacturer will help businesses make the best decision for their products.

How to Properly Handle, Store, and Ship Your PCB

Proper PCB handling, storage, and shipping methods are critical to ensuring your printed circuit boards arrive in perfect condition. Even the best-designed and-constructed PCBs can be easily damaged when not handled correctly, leading to costly delays and repairs. So, to help ensure your PCBs arrive in perfect working condition, consider utilizing stricter quality control measures that save both time and money in the long run.

How Long Do PCBs Last?

PCBs can last for many years when treated with care and stored in the proper environment. By following advice from industry experts and partnering with a reputable manufacturer, businesses can ensure that their printed circuit boards have a long lifespan.

What Is the PCB Solder Mask Layer?

The solder mask is a layer on printed circuit boards that helps protect the copper circuitry and provides a consistent surface for soldering components. Choosing the right solder mask material and process is critical to ensuring reliable soldering and the long-term performance of the circuit board.

What is PCB Etching?

PCB etching is the process of removing excess copper from a printed circuit board. After the etching process is complete, only the required circuit remains. Let’s take a deeper dive into the different PCB etching methods.