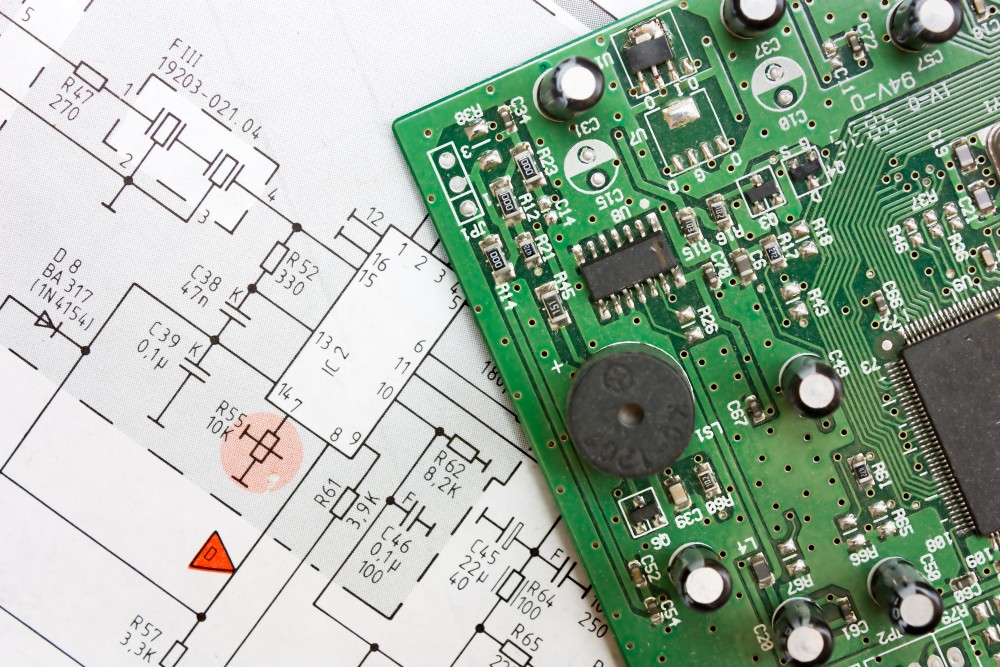

IoT (the Internet of Things) products have been on the rise in recent years. Their popularity won’t be flatlining anytime soon. As devices get smaller and more complex, knowing how to design PCBs (printed circuit boards) to fit the consumer market is key.

Let’s talk about how you can improve and optimize your PCB design for the IoT trend so you can future-proof your business—and take it to new heights.

What Characteristics are Needed for IoT Products?

What is IoT, anyway? The Internet of Things refers to the network of physical objects that contain software, sensors, and other technologies so they can connect and exchange data with other systems and devices using the Internet.

Things you’ll want to consider in PCB design for IoT devices are:

Comfort and Flexibility

Now that so many devices are wearable, building for comfort and flexibility is critical. Buyers won’t want to wear something bulky or cumbersome. They want something that fits seamlessly into their days. Most are buying because they think it’s cool, fashionable, or convenient. So make their lives hassle-free, not itchy and frustrating.

Small Size

People want to use their IoT items on the go, meaning they’ll have to be just the right size and weight to keep in pockets, purses, etc. If something’s bulky or heavy enough, they won’t want to bring it with them. It’ll start getting less and less use, and they’ll wonder why they even bought it in the first place.

Connectivity

If someone’s using a wearable device or something they’ll keep on their person frequently (like a smartwatch, medical monitoring device, or cell phone), or even if it’s large and home-based (such as a smart refrigerator, vacuum cleaning robot, or sound system), it’s important to realize they purchased these smart products with a focus on connectivity.

Otherwise, they would have just stuck with older, likely cheaper versions. If they invest in IoT products, they expect it to be worth it. They expect things to work and to keep them connected. Without useful connectivity, they may regret their purchase decision.

Durability

Your customers lead busy lives, so they demand high performance. They need their devices to hold up to daily wear and tear. After all, no one wants to replace something they just bought. Design for lasting strength to give customers confidence in your products. Returns and bad reviews upset customers and project managers alike, so it’s best to choose high-quality materials from the start.

5 Tips to Follow When Designing PCBs for IoT Products

Because IoT products are complex, there are many factors that go into the production process. PCBs play a major part in it, so knowing what to design your PCB around will help you achieve smooth product manufacturing and successful production.

Over-communicate with Involved Departments

When one department makes a change, it can affect another department’s work. All relevant team members—from electrical engineers and designers to mechanical engineers—have to be on the same page throughout the whole prototyping process for things to go off without a hitch. Fortunately, today’s CAD programs make it easier for all parties to see updates on products, especially when working remotely.

Prepare for Space Limitations

The market demands smaller and smaller products. Remember the convenience factor—people crave what they believe will make their lives easier. Health tracking watches don’t leave much room for wide PCB layouts, for instance. With IoT products, you’ll want to utilize multiple PCB layers.

Build vertically instead of horizontally whenever possible. You’ll save surface area and fit more into a compact space. Work across departments to find the optimal PCB layout and manage space effectively.

Always Keep Consumers in Mind

Keep in mind what the end product is and what it is for. If you’re designing a PCB for a watch, and the value proposition is its minimalism, don’t try to make it more complex and bulky.

If you’re impressing your colleagues but irking your customer, your product will be a flop. Keep in mind the trend of minimal designs, standard-size parts, and replacing metal with plastic when possible to keep costs lower.

Consider the Power Supply and Connectivity Factors

Each connectivity decision you make will impact compatibility, power consumption, certifications, and more. The earlier in the process you can pinpoint the right solutions for your technology, the better. That could mean weighing your options for WiFi, Bluetooth, or cellular. Valuable layout practices for PCB design in IoT products include:

- PCB Stack-up. This one is useful for thermal performance. Designing PCBs this way can help you avoid issues with things like power delivery, signal transmission, and antenna feeds.

- Stitching Vias. This PCB design type will enable proper current returns and diminish noise interference, especially when combined with grounding, which we’ll touch on next.

- Grounding. Because the ground area tends to be limited as far as small devices go, it’s still important to ensure appropriate grounding is built-in for safe, efficient thermal dissipation and optimal RF performance. This must be considered no matter what size product you’re working with.

- Antenna Performance. When selecting an antenna, think about criteria like orientation, gain, directivity, and form. You should also pay careful attention to objects in the antenna’s immediate field because things that are too close can lead to detuning—which will not thrill your buyers.

- Power Analysis. Since customer usage is bound to fluctuate throughout each day, create a consumption formula to accommodate these fluctuations and make sure your device can maintain top-notch function. In your PCB design, calculate a clear projection in terms of power consumption over the product’s target lifespan—especially critical in battery-powered technology.

Test Early

As with any PCB design, testing early and often can cut back on spending and headaches throughout the pcb manufacturing process. Focus on maintaining an agile mindset to keep things moving and avoid any major timeline setbacks. Don’t just assume that one component will work with all the other components in the product since PCB design for IoT products includes lots of intricate moving parts.

Detect problem areas as soon as possible so you can fix them and keep things running on schedule—reducing downtime and making for happier employees and customers alike.

Partner with an Experienced PCB Manufacturer

Getting a PCB design prototype in place is the first step—figuring out the logistics of manufacturing is the next. Teaming up with a seasoned PCB manufacturer can help smooth out the rest of your manufacturing process so you can expect efficient, problem-free days ahead. Get in touch with us to receive a quote on your upcoming manufacturing project.