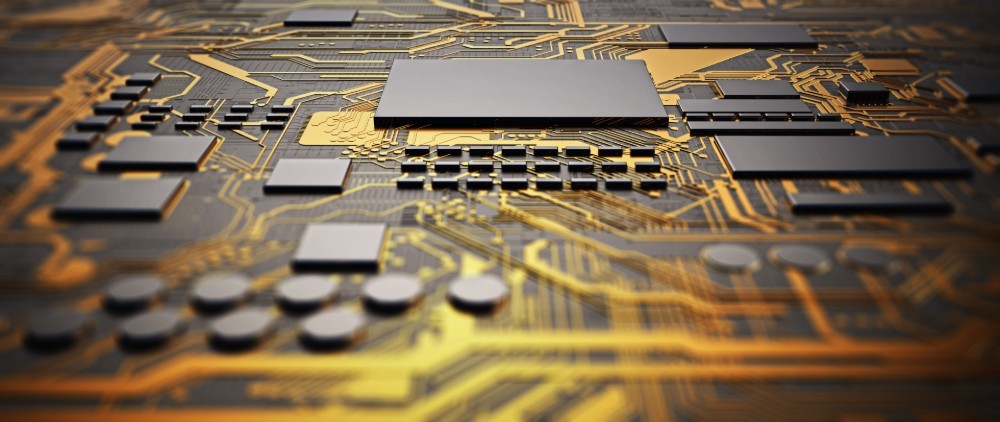

Printed circuit boards seem to be ubiquitous, and they seem to show up in places that people are unlikely to expect. You might be pleasantly surprised to find out that you are using PCBs on a daily basis in more places than you think. Printed circuit boards are in more than just commonly used electronics, and because they are so ubiquitous, PCBs have a unique past and there are some fascinating facts about them, too.

5 Interesting Facts About PCBs that You Might Not Know

These little green boards do some rather amazing things. They are thin boards made of insulating materials. They are usually coated with a metal like copper. To make the boards work, the metal is etched to create paths for electricity to travel to each component, which is soldered onto the board.

#1: The First PCBs Were Funded by a Music Printing Company

The Father of the Modern Printed Circuit Board was an inventor from Austria named Paul Eisler. When he invented the PCB, he was working at a music printing company. The company liked his idea, and they ended up funding it. He was working on a radio in 1936, but they were not mass-produced until the 1950s. There is evidence that some people were working on something like them in the 1890s.

Eisler would be interested to know how many musical instruments use PCBs today. For example, electric guitars and keyboards could not function without PCBs.

#2: PCBs Use Copper Traces Not Wires

Despite these green boards being used in electronic devices, they do not use wires. We usually associate wires with electricity, so this fact comes as a surprise to many. The device works with traces that transmit the energy. Electrons move through the boards using copper traces. Because there aren’t any wires to worry about, PCBs can be small.

The reason that copper is used is that the metal is conductive. Signals can move through the PCB without having any electricity drop on the journey. Fortunately, PCBs do not need much copper, as one ounce can be spread over a square foot of a PCB at about 1.4 thousands of an inch thick. Also, copper is inexpensive. It keeps PCB affordable for major manufacturers, small businesses, and hobbyists alike.

When looking at why copper is so successful at conducting electricity is that it has one valence electron or a free electron. These free electrons can move between atoms without much resistance. Electrons hold the particles that hold electricity. So with copper, the electronic signals can move without slowing down or losing power.

#3: The Majority of PCBs are Green

PCBs are almost always green. But, manufacturers can choose different colored boards for filling different needs in their products. However, green is still the top choice. The color is popular because it is easy on the eyes, and it is easy to inspect because flaws in the traces show up clearly. Some people believe that the traditional PCB green color was first used by the military as that color was standard for them.

But, other colors are growing in popularity because they show the different purposes of each board. Some manufacturers use different PCB colors to show their revisions. Some also rely on different colors because of the transmission properties, reflective properties, and absorbance, too. While motherboards are usually made in green to show they are motherboards, other PCB types have color codes for identifying them.

The colors of the boards do not speed up or slow down the board. But, the resolution changes when different color solder masks are used. For example, when a green PCB has a red or blue, some other colors have less resolution. Transparent solder is the best, with the highest resolution.

#4: Several Potential Components Consist of a PCB

PCBs might look like simple structures with fancy patterns on them, but this couldn’t be farther from the truth. They are loaded with components that do a variety of things. You may have heard of components like resistors, batteries, transformers, diodes, and capacitors. But PCBs also have lesser-known components like potentiometers, inductors, relays, and ruses. These little components do important things with the electricity that moves through the copper.

PCB boards can be drilled, laminated, plated, and coated. Most of the components are soldered into place. Some PCBs are made by hand, with hand-drawn traces. Others are made with special printers to keep everything in straight lines and right angles.

There is no magic number of components that need to be soldered onto a PCB, since each board is created to do something different, the number of components varies dramatically. Along with the copper traces, the little components are what customize the role of the PCB. Some PCBs have components only on one side. While others have components on both the top and bottom of the boards.

#5: PCBs are Vital in Space

Printed circuit boards aren’t just used on Earth, they are used out in the vacuum of space. Because they require minimal amounts of electricity and they are small and lightweight, they are ideal for space flight. The little circuit boards are incredibly useful, and they’ve been used since NASA first sent spacecraft into the great unknown. In fact, they are so helpful that Apollo 11 astronauts used them to get to and from the moon. They also helped the Apollo 13 astronauts make it home after the failure of the oxygen tank.

Printed circuit boards might not look very complicated, but they are. They are necessary components of technologies and systems, as they control the electricity they use. Most gadgets at work and home have PCB boards, including everything from your computer mouse to your microwave oven, smartphone to automobile, and remote control to HVAC units. These boards have been around for over a century, and people continue to innovate with them. They are expected to be around for a long time and to make their way into more devices.