In the 1960s, industry engineers proposed a new term — MEMS — but it wasn’t until the ’80s that they put it in commercial use.

The meaning behind MEMS has shifted throughout the last two decades. The phrase is now used to denote both a specific kind of device and a method of manufacturing.

When talking about it as a device, it usually refers to a “micro-device” that involves both moving elements (mechanical parts) and electrical functions. There are a variety of devices that can be developed and improved using this mix of electrical and mechanical capabilities, such as microphones, speakers, accelerometers, and pressure sensors.

MEMS manufacturing processes could replace standard macro-scale machining and assembly methods. The most exciting part? These microelectromechanical systems can be so small that they are invisible to the human eye!

Here is more in-depth information on these small yet powerful wonders of the electronic industry.

What Does MEMS Mean?

MEMS stands for microelectromechanical systems.

In a nutshell, it’s an electronics manufacturing method for microscale devices including transducers, sensors, switches, actuators, pumps, gears, and so on. You can look at MEMS technology as an extension of conventional integrated circuit (IC) fabrication. The one main difference is that using MEMS, you can manufacture mechanical parts such as springs, beams, and gears. Standard IC technology can only be used for manufacturing diodes, insulators, transistors, and conductors.

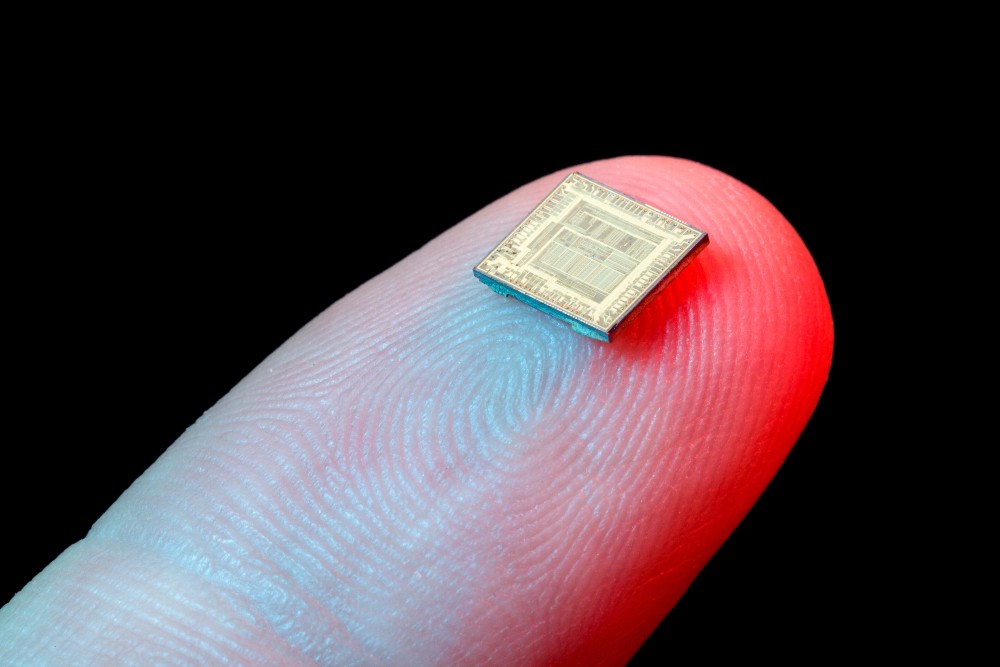

The components of microelectromechanical systems are made up of exceedingly tiny parts. So little, in fact, that the whole MEMS device can be as small as one to 100 micrometers in diameter. To give you a sense of scale, one millimeter consists of 1,000 micrometers. Of course, MEMS of that size are not visible to the human eye.

The building blocks of devices using MEMS are microsensors and microactuators, which convert one energy type to another. There are two types of sensors: those that sense physical motion and those that transform that motion into an electrical signal.

History of MEMS Technology

The roots of microelectromechanical systems can be traced back to the silicon revolution and two significant inventions of semiconductors in 1959 — the monolithic IC chip by Robert Noyce and the MOS transistor by Dawon Kahng and Mohamed M. Atalia. The development of MOS transistors (or MOSFET) on IC chips allowed for the miniaturization of electronic components and devices.

Engineers realized that MOSFETs and silicon chips could interact and receive input from the environment and process movements, chemicals, and light. This established the groundwork for creating micromachining technology based on silicon semiconductor technology. At the beginning of the ’60s, Honeywell developed one of the first isotropically micromachined silicon pressure sensors.

In 1965, Harvey C. Nathanson invented the resonant gate transistor, a modification of MOSFET today.

An early example of a MEMS device is the resonant gate transistor, an adaptation of the MOSFET developed by Harvey C. Nathanson in 1965.

Even though academic interest in MEMS sparked during the ’80s, mass manufacturing only began a decade later.

MEMS technology is most commonly seen in industries such as the military, consumer products, automobiles, aerospace, pharmaceuticals, industrial applications, and biotechnology.

Nowadays, many of us carry a few MEMS devices around, such as smartphones, fitness bands, and smartwatches. Other common products include airbag sensor accelerometers, computers, inkjet printer heads, blood pressure sensors, and microvalves.

In the 2000s, aeronautic gyroscopic devices used in airplane cockpits, for example, weighed

several pounds and measured four inches in length. Two decades later, we now carry this technology in the palms of our hands. In our smartphones, the MEMS gyroscopes weigh less than a milligram and are about the size of a grain of sand.

How Does MEMS Technology Work?

MEMS sensors are made up of a suspended mass between two capacitive plates and are considered chip-based technology. When the sensor is angled, this suspended mass changes in electrical potential. Capacitance changes are used to quantify the difference.

MEMS researchers and developers have created an enormous variety of microsensors for practically every imaginable sensing modality over the last few decades. These microsensors range from pressure, temperature, and inertial forces to magnetic fields and chemical types.

Several types of sensors may be used to detect changes in the system’s surroundings. Once the sensor generates the input, the information is then processed by microelectronic systems, which then signal that it’s time for microactuators (or the mechanical components) to do their part. Microactuators react to their environment by moving, regulating, positioning, pumping, or filtering the environment. Because of this, MEMS can be used to regulate the environment for a specific outcome.

Advantages of MEMS

The benefits of MEMS technology are many. While other sensors have to deal with space limits, MEMS sensors don’t, as they employ micro-machine components that are so small that each sensor may fit in the palm of the hand. Additionally, they have a small thermal constant and can operate under extreme temperatures that range from 40 to 85 degrees Celsius.

Microelectromechanical system devices can withstand elevated levels of stress, vibration, and radiation — all while remaining highly sensitive to environmental input.

It is great for commercial mass-production, as MEMS can be batch-manufactured in large arrays and easily integrated into systems.

And on top of all that, they come with low cost, making them the present and the future of the electronic industry.

Manufacturing a MEMS Device

The MEMS market is expected to increase at an annual rate of 8.3% by 2024. To keep up with the demand of the current shift toward personalized gadgets, the industry has to manufacture devices in the highest quantities. And almost all of them rely on MEMS technology.

Microelectromechanical devices could be life-changers when it comes to medical obstacles, such as restoring eyesight or hearing. Scientists are constantly working to overcome challenges in the medical electronics industry. By utilizing MEMS, doctors could even reactivate paralyzed regions of the body. After measuring the brain’s electrical impulses, scientists could mimic those signals to stimulate the specific nerves needed for movement.

The number of fabricated MEMS devices is exploding, and that number is only expected to rise. By 2026, the MEMS industry will likely be valued at $18.2 billion.

In the electronics industry, MEMS seems to be one of the most prospective and future-oriented. If you’re evaluating if it would be wise to start a line of business using microelectromechanical device fabrication, make sure to do proper research on different electronics manufacturers so you can be sure of what you’re looking for.