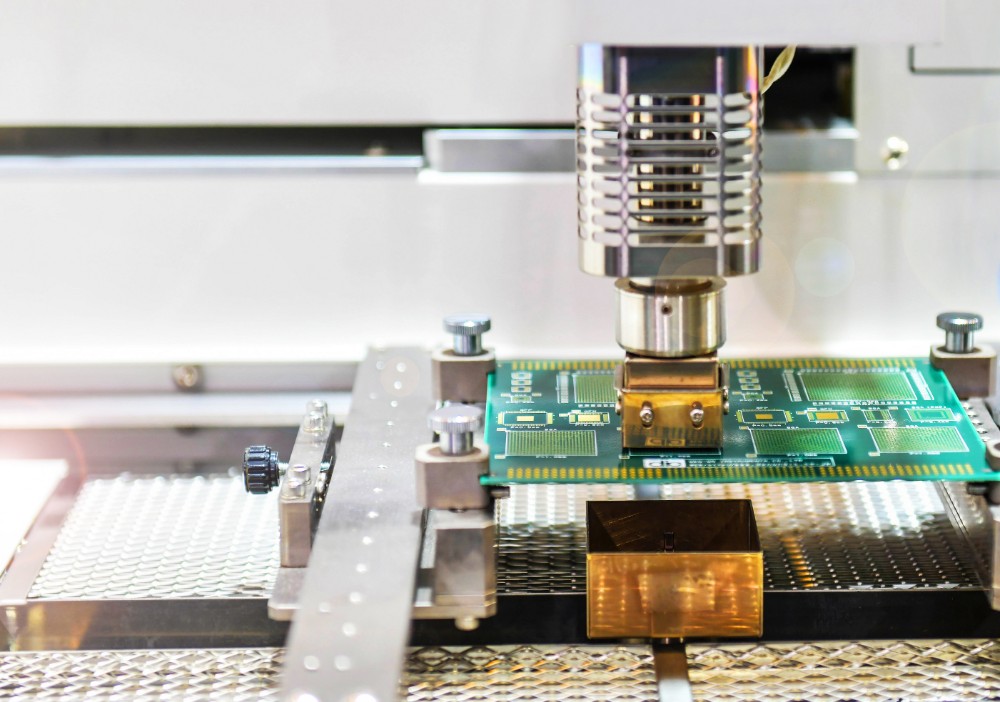

Any business that delivers manufactured products to its clients must have a quality assurance program in place. PCB manufacturing isn’t any different. The real challenge comes with keeping the process before, during, and after manufacturing within your set quality standards.

Let’s keep in mind that quality assurance is different than quality control as the two are often used interchangeably. With quality assurance, you pay attention to every stage in the manufacturing process, but with quality control, you look at the final results via testing.

When designing and manufacturing your printed circuit boards, there are five quality assurance processes that should be met each time. If you’re searching for a quality PCB manufacturer to bring your designs to life ensure they have the processes below in place before signing the contract.

Quality Engineer On-Site

If your business is dedicated to quality assurance, then your printed circuit board manufacturer should have a high-quality engineer on-site. The engineer is the face that stands behind the product. Without a well-trained engineer, you run the risk of mistakes at any stage of the manufacturing process.

Think about it this way:

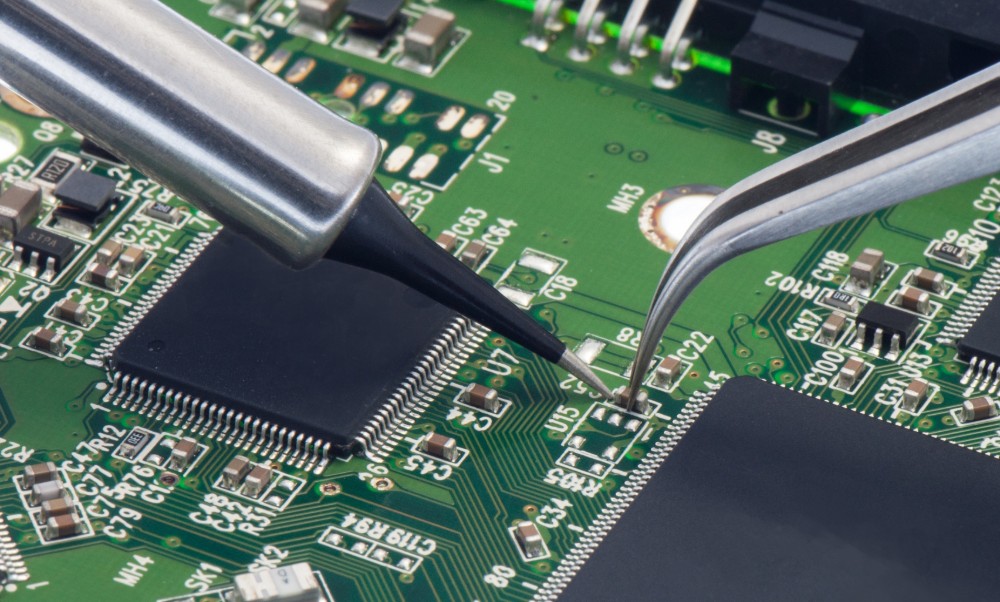

The engineer is directly involved in the PCB assembly process. They add value to the process by providing knowledge and experience that helps improve designs.

They also look at data to avoid problems before they even begin. A well-educated and trained engineer can help deliver an exceptional, high-quality PCB that exactly meets your needs.

Before deciding to work with an outside partner, you should look at whether or not there are well-trained engineers on staff. Don’t be afraid to ask about their experience, certifications, and licenses. It is also helpful to inquire about previous projects their engineers have advised on.

You can do a quick search on the contract manufacturer’s site, on their staff page or about page, there should be a mention of the positions they employ and the certifications they have obtained as quality is key in printed circuit board manufacturing.

Risk Management

Managing risk involves planning for potential problems, using data obtained through risk assessment. With risk management, manufacturers can lower their costs because they avoid having to pay for fixing problems.

Ensuring your contract manufacturer has an organized risk management system also helps them meet your crucial deadlines as steps are already in place for quality products. The best plans stop problems before they start, and the PCB manufacturer you choose should be able to clearly communicate their risk management plan to you.

If you’re still wondering what do I look for when it comes to risk management in a PCB partner, then this should help.

A high-quality contract manufacturer should ensure their client obtains the necessary components to build their printed circuit board before accepting the projection. Otherwise, they have no way of knowing if they can complete the project in your required project timeline.

AQL Testing

In many situations, problems happen when businesses scale. When they only have a few customers, businesses are able to take their time and meet their clients’ needs with quality products.

But:

As businesses grow and they begin manufacturing for clients en masse, it becomes easier to make mistakes as speed becomes part of the goal.

This is why acceptable quality limit (AQL) testing is vital.

As your manufacturer speeds through your project to meet deadlines, defects and quality issues are sure to happen. With AQL testing, batch quality is determined by only testing part of it. AQL involves testing a sample and looking for a preset limit that is presented to customers who can accept or reject the batch.

You should work together with your contract manufacturer to set limits for quality control and quality assurance before signing the contract. A quality contract manufacturer should include this in the contract to detail the predetermined AQL numbers so there is no misunderstanding.

First Article Approval

Another process that you should agree upon with your PCB manufacturer before the product is delivered is First Article Approval. While the AQL is agreed upon by both you and the manufacturer, this process is typically taken on by the manufacturer.

Once the first unit is produced, the manufacturer inspects it to be sure the manufacturing process is functioning at the highest quality level.

With First Article Approval, the manufacturer looks at the efficacy and efficiency of the production. The goal is that the quality can be reproduced in each unit. They closely inspect the precision of the unit’s calibration to prevent defects in the following units.

When searching for your contract manufacturer, ask if they have First Article Approval already in place, and if not, would they be willing to add this into the process.

Quality Certifications

Quality Certifications

An exceptional electronics manufacturer should have certifications that matter in the industry they serve. These certifications show that the manufacturer has the necessary space and equipment to produce top products.

They also have highly skilled, properly trained employees who can meet preset standards, established by the certifying agencies.

You want to see that the contract manufacturer you hire is dedicated to quality, and top certifications show that they stick to rigorous standards. It isn’t easy to become certified, so when companies achieve them, they show their true dedication to delivering the best.

Questions to Ask Your Contract Manufacturer

Before you sign the contract with your printed circuit board manufacturer, there are several quality assurance questions you should ask. A few of these include:

- Do you use routine audits during manufacturing?

- Is it possible to see the audit results?

- Can you take a walk-through of the facilities to see how they care for their facility?

- Will they do a management review with you?

- What happens when products are not conforming to their or your standards?

- Will you have the chance to see prototypes or first units?

- Do you get to approve changes they make to the design?

Choosing a PCB Team with Quality Standards in Place

Before hiring a contract manufacturer, you should have a good idea of what they stand for. They are creating a product for you, and it will bear your name. Often, the relationship between client and manufacturer is like a marriage, where there will be moments where all goes well and times when troubles arise.

You should be able to trust that your manufacturer will solve problems and deliver a product that exceeds your standards. When looking for a PCB manufacturer, be diligent as you conduct your search to find the best contract manufacturer that recognizes the importance of quality assurance standards.

You shouldn’t be the first customer who asks about quality standards; the manufacturer should present them to you before you ask.