Creating a new electronics product is no walk in the park — there is much research, planning, and strategy involved. Before diving in, be aware that it is a very long and time-consuming process with many rounds of revisions, trials, and errors. Bringing a new product to market is not quick or easy.

Each company works differently, so here’s a high-level overview of the typical electronic product development process.

What Is Product Development?

The process of product development includes all the steps it takes to create a new product — everything from inception to schematics, manufacturing, shipping, and selling. For your product to be successful, you need to do in-depth market research to understand your customers’ needs.

Many people are involved in the product development process including designers, development teams, project managers, engineers, financial analysts, and often executives who oversee the process and give the “okay” to start each new phase.

The Electronic Product Development Process

As with most projects, there are many stages of the completion process. In electronic product development, it’s best to complete each step in full before moving to the next.

Electronic product development moves quickly and often has deadlines that need to be met. Many people rush the steps, but that usually backfires — sometimes publicly. The worst thing to do is to push product development to the manufacturing phase too quickly.

You’ve probably heard of the Samsung Note 7 phones exploding on airplanes. No company wants their name connected to a PR nightmare like that, in addition to not wanting to provide a product that poses a potential threat to human life, of course.

Instead, work efficiently and in discrete steps to ensure your electronic product development goes off without a hitch, stays on track, and results in a highly successful end product.

Market Research and Inception

“Quality planning consists of developing the products and processes required to meet the customer’s needs” — Joseph M. Juran.

The early steps of developing a product are crucial and often get overlooked. Creating products “just to have something new” isn’t the best business decision. If your product won’t sell in the end, why even make it? It’s great to bring new ideas to the table, but without the market for it, you will end up losing a lot of your money and time.

Unless it’s a particular circumstance where you’re hired to create a unique product on a small scale, make sure to dive deep into market analysis before starting the whole process.

Here are some things to consider during your research:

- Make sure there is a need in the market.

- Evaluate how difficult it will be to sell the product.

- Research your competition and similar products.

- Is there major competition, or are you the one paving the way for this type of product?

- Will you be able to patent the new product? Keep in mind that although it shouldn’t hold up production, patenting takes a long time and can be an expensive process.

While finding competition in the market can deter some inventors from proceeding with a product, it shouldn’t. It’s a big misconception that competition is a bad sign. Assuming you have enough differentiation and a low enough barrier to entry, competition only means there is market demand for the product — which is precisely what you’re looking for.

Design Phases

Now that you’ve found a place in the market for your electronics product, it’s time for the next phase — design.

The design stage can be different for every company and circumstance. Some will start with proof-of-concept (POC) prototypes, make 3D designs, or jump straight to schematic designs.

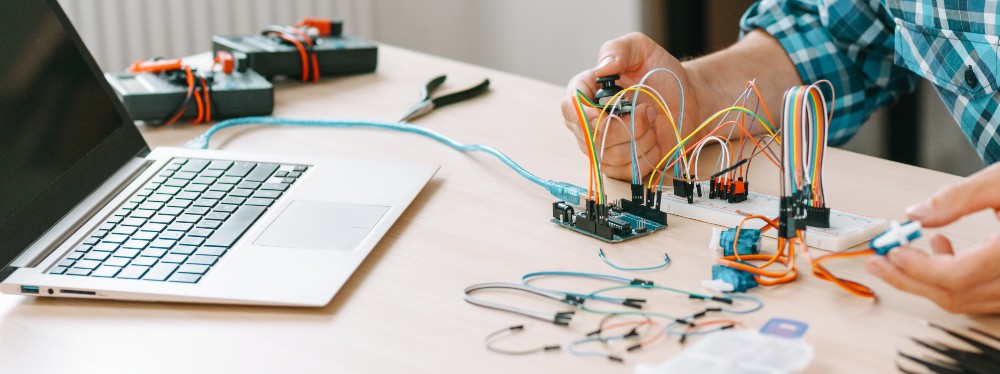

A good question to answer at this stage is: does your concept actually solve the problem consumers are experiencing? Answering that question is the purpose of the proof-of-concept prototype. It is an early prototype that is made with off-the-shelf development kits. It’s not something you could ever market due to its size and looks, but it’s not expensive to build, and it will give you a preview of your concept.

After you make sure your idea solves intended customer problems, it’s time for a more creative endeavor — creating a 2D and then 3D model that will give you a feel for the device.

Circuit schematic design shows how the printed circuit board will work. It looks and functions similarly to a blueprint for a house. Unlike a POC, it is custom-designed for your future electronic device.

After POC or schematic designs are finished, design the PCB. This step is typically done by a design or electrical engineer. PCB layout is crucial for the proper functionality of your end-product. It needs to be practical, made in a realistic size, convenient for your 3D model, and cost-efficient.

Debugging of any potential issues is done during the design stage as well.

Prototyping and Testing

What looks good on paper or makes sense to make now might not work exactly as you plan, which is why prototyping and testing are essential to the development of a new product.

This stage can take many rounds of revisions and changes before you find something that works effectively. Don’t be discouraged. It’s a standard procedure that you need to go through.

This phase will also highlight any issues so you can fix them before you head to manufacturing.

Figure Out Costs

When prototyping is complete, you should calculate the cost of mass-producing your new device. Things to consider are the materials, and of course, the cost of the product assembly.

Figuring out the bill of materials will give you an idea of what the end product will cost you and what materials are needed.

Make sure your budget accounts for production. If not, try to enact some smart cost-saving measures that won’t significantly affect the quality of your product.

Manufacturing Electronic Products

Once you’re sure your product works and the production cost is within your budget, it’s finally time for manufacturing.

Some companies have the infrastructure to manufacture in-house, but many companies choose to work with a printed circuit board (PCB) manufacturer or electronics manufacturing service (EMS) provider instead.

In most cases, it’s best to work with an EMS provider that can handle every step of the manufacturing process instead of sourcing different parts and phases of development from other factories.

Overseas manufacturers can be alluring as they are usually cheaper in cost, but there can also be more risk involved, especially with the COVID-19 pandemic. Onshore manufacturers are often the more reliable option. If you choose to take this route, make sure you know what to look for in an onshore manufacturer.

A seasoned PCB manufacturer can also guide you through any potential issues that may arise and help you fix them before they turn into bigger problems. Partnering with a PCB manufacturer means they can also help with future products in design and prototyping.

You should also do testing after manufacturing to make sure the process went smoothly. Just because it worked in the prototyping phase doesn’t mean products made it through manufacturing successfully. Just remind yourself of the Samsung Note 7 case. It’s better to do testing twice (or many, many times in that case) than to send off a malfunctioning product.

Developing an Electronic Product

When you’ve gone through all the product development processes, the only thing left is to market and sell your product. Easier said than done, but keep in mind that you’ve already come to the final stage.

Conducting research, planning accordingly, and testing a lot will enable you to design an electronic product successfully. An electronics manufacturing service will also ensure that the development and production stages run as smoothly and efficiently as possible. Explore all the options available so you can make the best decision for your product.