When designing or manufacturing printed circuit boards, there are many factors in the process to consider to ensure your product works properly.

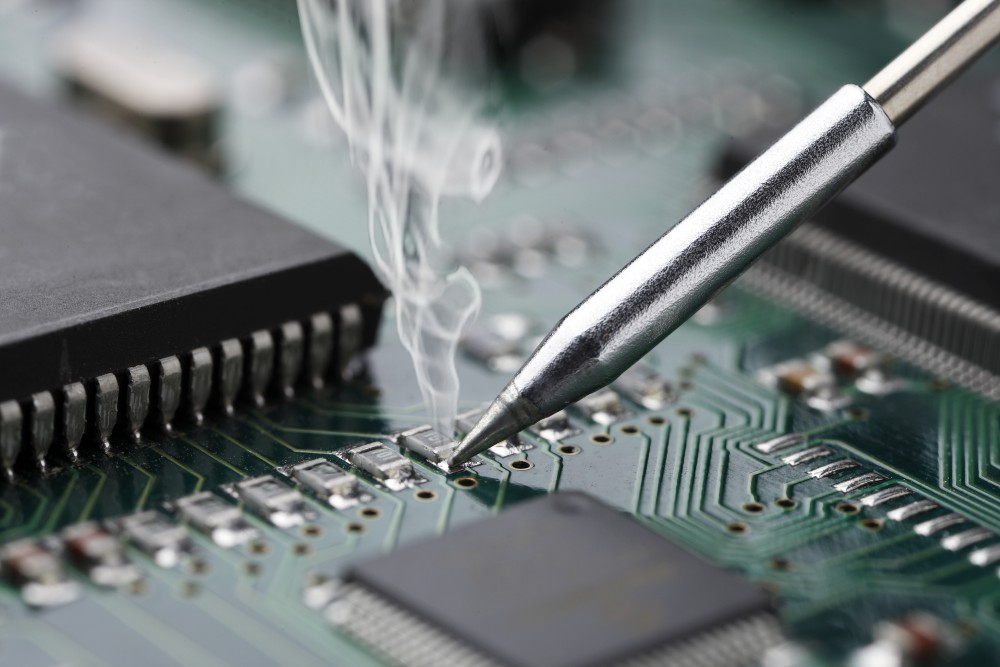

Soldering is a crucial component in the electronics manufacturing process. Soldering is the process of attaching two or more components together using a glue-like metal substance called solder.

The soldering technique you choose depends on your needs, materials used, and other specific factors like high heat resistance or flexibility requirements.

Before choosing a soldering process, you must know what each method has to offer.

Picking the wrong soldering technique can lead to product failure or damage to your PCB. Read more to learn about the different soldering methods and what materials are needed for soldering.

Soft Soldering for PCBs

Soft soldering is a popular choice in the industry and the best choice for attaching smaller, compact, fragile components to a printed circuit board. The components used in soft soldering will often have low-liquefying temperatures that break down in high heat.

Soft soldering liquid needs to stay below 752 degrees Fahrenheit (400 degrees Celsius) to avoid breaking down the board and components. When temperatures rise above this, the process is called braze soldering.

During soft soldering, a tin-lead alloy is used as a metal space filler and is heated by a gas or electric torch to attach components to the board.

Soft soldering is not as durable as other methods and does not make strong joints, giving it the “soft” title.

Hard PCB Soldering or Silver Soldering

Hard soldering (also known as silver soldering) produces stronger joints than soft soldering does for your PCBs.

Hard soldering is normally used to combine metal parts — mainly gold, silver, brass, and copper — at around 600°F. A blowtorch is used for melting.

You must use boric acid and alcohol to keep the solder and surface clean during this process if you want a successful component attachment during your PCB manufacturing.

The term “silver soldering” is used with this method when the solder alloy is made of silver.

Braze Soldering

Brazing uses the highest temperatures and creates the strongest joints compared to soft and hard soldering.

Brazing is similar to hard soldering because the metal components or pieces are attached through high heat.

The difference in brazing is that it melts the metals at the base to fit the filler metal designed for your board.

Braze soldering is an easy process to automate for mass production, works best to connect two separate PCBs, and causes less thermal deformation.

Wave Soldering

Wave soldering is utilized for assembly in through-hole processes or surface-mount technology (SMT). It is used for bulk assembly of printed circuit boards.

The PCB passes over a pan of molten solder that looks similar to a wave pool (that’s where the name comes from). When the circuit board comes into contact with the solder, the circuit board components become attached.

Before wave soldering for SMT, components must be glued to the board.

SMT methods have become more popular than through-hole, making wave soldering a less popular technique of choice. Wave soldering has subsequently been replaced by reflow soldering.

Reflow Soldering

The reflow soldering process involves attaching components to the board with a heated soldering paste. The soldering paste is heated and turned into a molten state, enabling pads and pins to be connected.

Reflow soldering results in a permanent attachment.

Materials Needed for Soldering a PCB

While some materials used in the manufacturing and soldering processes may vary from project to project, four essential materials will be used during every soldering procedure.

- Soldering iron: A soldering iron is the source of heat used in the soldering process. This is a pen-shaped metal tool that allows you to manipulate the solder. The parts of a soldering iron include the tip, wand handle, solder wick eraser, and a rest for when it’s not in use.

- Soldering paste: This is a gray putty that attaches the leads of your components to the board.

- Solder Flux: Solder flux is a chemical cleaning agent. It helps remove rust, prevent future rust by keeping air out, and allows your soldering paste to be applied easier by preparing the surface.

Pick the Best Soldering Process for Your PCB

The soldering method you implement depends on the requirements, capabilities, and materials used on your printed circuit board.

Before choosing a soldering technique, make sure you know what’s best for your product for lasting results.

Partnering with an electronics manufacturing service or company can help with soldering and the rest of your PCB manufacturing process.