Printed circuit boards need to be prototyped before they go into production. With a prototype, you can test it to see if the components work together efficiently and effectively. Without a prototype, you run the risk of your manufactured PCBs having fatal flaws that result in costly recalls and repairs. So, before you begin the production of PCBs, having a prototype is an essential step to produce high quality and functional PCBs.

What is a PCB Prototype?

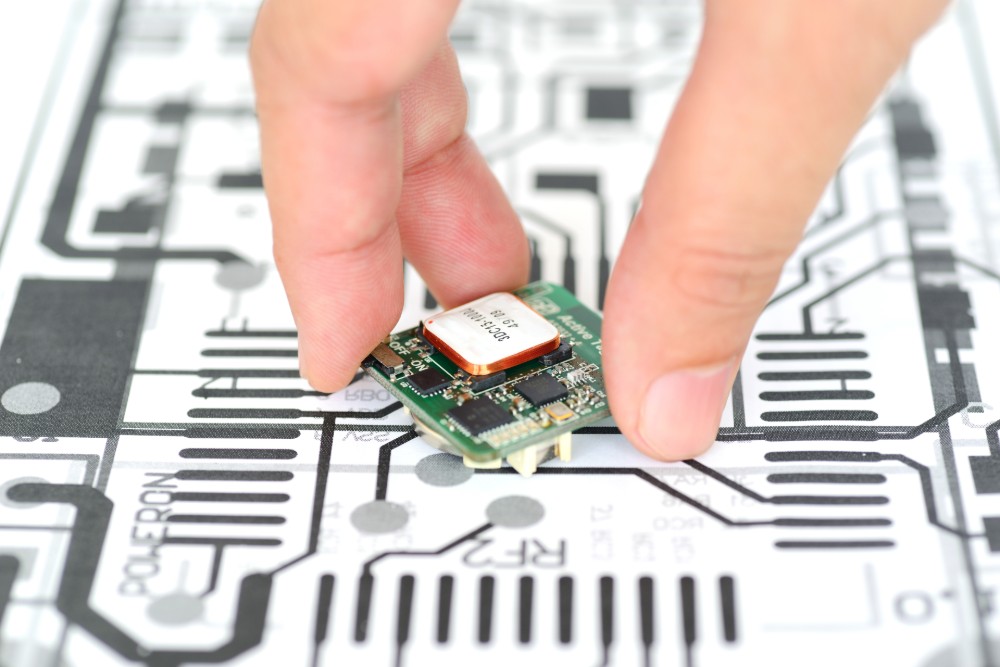

A PCB prototype is one of the earliest steps in the manufacturing of an electrical device. Each device needs a PCB, so manufacturers will design a prototype to be sure it gets the job done. A PCB uses conductive tracks soldered onto a metal or epoxy board to move the current through it. With a prototype, manufacturers can find out quickly whether the PCB sends the current to power the device.

The prototype is the sample that lets the manufacturer test the design. They are the basic functionality test that each manufacturer needs to do before committing to a design and mass producing them.

How Are Prototype PCBs Produced?

There are two main methods for prototyping a PCB –

Through-hole Technology

Through-hole technology is the traditional method of manufacturing PCBs and prototypes. This method involves inserting leads through holes on a single side of the circuit board. Then, the leads are soldered to the copper or other metal layer on the other side.

Manufacturers who use through-hole technology often make prototypes by hand. They usually have some issues because they don’t always have all of the same robust components that go into making the final version. These hand-made prototypes tend to be simple in design, and some do not last through the challenges that arise during the testing process.

Surface-mounted Technology

This method of producing a prototype is more technologically advanced. Surface-mounted technology does not need leads. Instead, the components are soldered in place usually with a speedy soldering technique.

SMT allows manufacturers to create more precise, compact boards with complex abilities. Components can be added to both sides of the board because of the soldering technique. These prototypes tend to last through testing procedures because the process makes them stronger than those made through through-hole techniques. SMT prototypes can be made quickly and efficiently.

8 Ways to Improve the Quality of Your PCB Prototype

Fortunately, there are several ways to improve the quality of your prototype with a few simple techniques.

Create a Bigger Prototype

When making a prototype, you should make it larger than the one you plan to manufacture in mass. With a large prototype, you can see the components clearly and recognize how they work. This gives you room to make changes if the prototype needs to be debugged or probed during testing.

Use High-Quality Materials and Components

With high-quality materials, you can see exactly how the prototype will work when put through the rigors of testing. If you plan to use high-quality materials in your actual PCB, you should use the same materials in the prototype.

When you use low-cost materials, you run the risk of having problems with your prototype. To prove that the prototype will work, you should only make it the same way with the same materials and components that your final product will have. If you want to test it the way you will produce it, you should make the way you plan to produce it in bulk.

Produce Design Options for Your Prototype

Some manufacturers prefer to produce two or more prototypes so they can see which one works more efficiently. So, if you need to make design options, then make them. You can test both PCBs and find out which has the better design.

Choose a Quick Turn Prototype Assembly House

There are PCB manufacturers who will turn around a prototype quickly because they have the tools and components to do so. Others will need significant time to make a single prototype that meets the client’s needs.

If you need a quick-turn prototype, then you should turn to someone who specializes in speeding through prototypes. When you hire the right people to make your designs, you will get them quickly and to your specifications.

Ensure Coordination with the Assembly House

Before you order your prototype, you should have a chat with your assembler. They should be able to meet your needs by selecting options that they can make quickly and to your specifications. They know what works best and can make recommendations to you.

Hand Over Intelligent CAD Files

Your prototyping manufacturer will need CAD files with the layout for the PCB. The quickest way to get the prototype made is to give your manufacturer ODB++ files with all of the information they need.

Ask for a Design for Assembly Checks

As you work with your designer and manufacturer, ask for checks on the design to see if there are any problems with manufacturing. With an analysis, you should be able to see how effectively the prototype works so you can make necessary changes.

Have a Post-Build Inspection

To get the full idea of how the PCB prototype works can be determined by testing, but also by post-build inspections. Manufacturers use the automated optical inspection (AOI) tool and the 5DX x-ray to look for errors when comparing the design blueprints to the actual prototype. With these inspection tools, errors that are not visible to the naked eye are easy to spot.

By improving the quality of your PCB prototyping process in the beginning, it can save you time and money in the long run. Saving money on prototyping does not mean that you choose low-quality components or boards. The best way to save money is to make a prototype that is close to the final product so you can learn exactly what works and what does not work.