“It’s time for production” is what every PCB designer wants to hear.

But before you can start with production, you need to find a reliable and capable electronics manufacturer to help you with this venture.

You’ve already completed the most challenging tasks by conceptualizing and designing your product; now, you need an EMS company to get your product on the market.

What Are Electronic Manufacturing Services?

EMS is the process that helps turn your product idea into a reality.

An EMS company will design, manufacture, test, and distribute electronic components.

In most cases, a designer or engineer will bring their product concept to an EMS to help produce and distribute the end-product, and the EMS is not intimately involved with the design. Most electronic manufacturing service companies provide turnkey service where you can choose how little or how much you want them involved with each step of the production process.

EMS providers service an array of industries, including (but not limited to) healthcare, consumer electronics, automotive, and aerospace.

These services are also referred to as electronic contract manufacturing (ECM).

Key Services to Look for in an EMS Partner

The service you receive from an EMS provider will vary depending on the industry and requirements, but an ideal EMS partner will have the expertise to help you efficiently and successfully bring your product to market.

When looking for an EMS provider to partner with, they should be able to assist you in any or all of the areas below:

- Research and Development – This includes collaborating with your EMS on electronic innovations and specifications in the R&D process

- Co-design – The EMS provider will collaborate on the design and product development

- Prototyping – This includes your EMS partner helping with mockups and prototypes

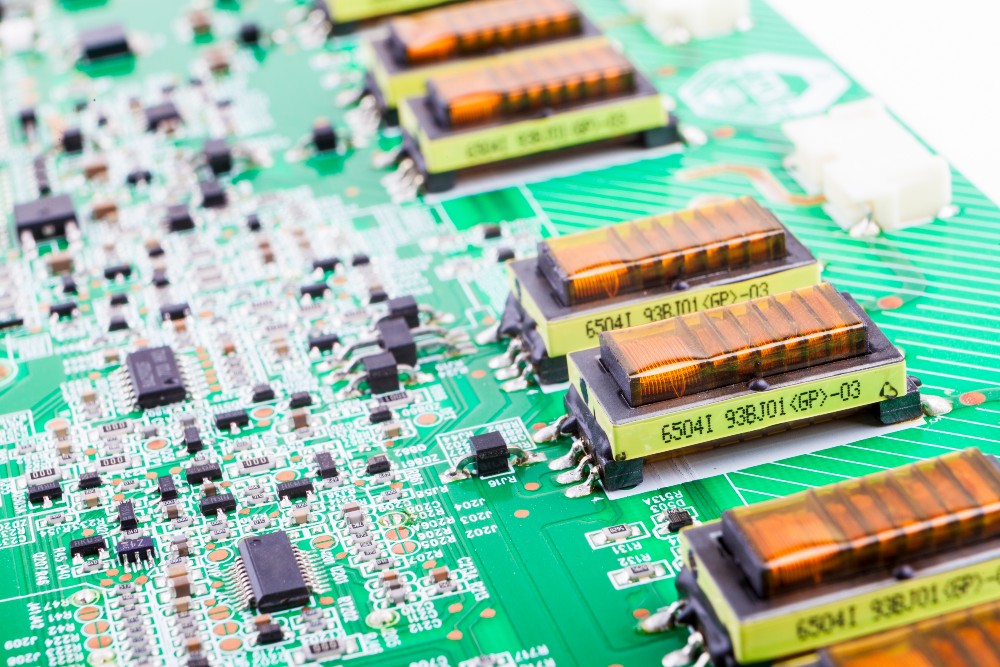

- Manufacturing – Your EMS takes on supply chain solutions, manufacturing, and box builds like PCBA and electromechanical assembly. PCB assembly includes soldering the circuits and contents to the board and making sure everything works as it’s supposed to.

- New Product Introduction – This involves assistance with industrialization, certifications, and product launch

- Smart Supply Chains – EMS partners provide supply chain management, automation, and the majority of the production process

- Product Lifecycle Management – Ensures your product’s development is on track and quality-controlled at each stage of the production process

- Post-Production Support – An important part that includes repairs, after-purchase support, and logistics

Characteristics to Look for in Electronic Manufacturing Services

Ensuring your product gets manufactured efficiently and accurately means partnering with a seasoned and technically skilled provider. Here are characteristics to look for in an electronic manufacturing services provider.

Experience

No matter the industry, teaming up with an experienced partner is the smart move.

A seasoned EMS provider has seen it all. They’ll know when to help and they’ll feedback when needed; they’ll also be proactive about potential problems. They will know what suppliers have high-quality materials and suggest design changes when necessary.

When looking for an EMS partner, a best practice is to research first and pick out a few you’d like to interview. During the interview process, ask about their experience and request testimonials. It’s easy for anyone to pretend they are an expert, but speaking to referrals and past clients will give you the best insight.

Design Proficiency

Whether you’re starting from scratch with a new design or moving forward with a common product, your EMS provider should be able to help with the design elements.

You’ll want to partner with someone who can streamline your design process, give feedback, and make tweaks to increase your product’s efficiency or cost; it should be a constructive partnership.

Most importantly, you want to make sure that your EMS partner can effectively bring your designs to life.

Technologically Advanced

Technology is advancing every day.

If you’re not at the forefront of these changes, the EMS partner you work with should be. They’ll be well-equipped to know what competitors are doing and how to implement the latest technology and trends to your PCB design to gain an edge over the competition.

It’s common to ask your potential EMS provider what kind of equipment they work with and where they source their materials.

You can also ask for a tour of their facilities to double-check that the equipment they are using is, in fact, what they say.

Unfortunately, some EMS providers will put on a facade and claim they have a manufacturing facility and fully-functioning processes when in reality, they outsource to another company. Seeing the facility in-person or virtually will help ensure that this isn’t the case.

Regulatory Compliance

Undoubtedly, an electronic manufacturing services provider needs to adhere to industry regulations. This includes laws, guidelines, and specs in every stage of the design, production, and delivery process.

Makes Good on Quality Assurance and Quality Control

An ideal EMS partner will have a rigorous quality control system; this shouldn’t be compromised.

The worst possible outcome would be to produce defective electronics that don’t work or lead to more severe scenarios, like harm to your customers. Without proper quality control, electronics of any kind can catch on fire or melt.

When looking for an EMS partner, make sure they have a track record of delivering quality products on time and without defects. A QA system will result in faster turnaround times, no backlash about defective products, and also keep your budget at bay.

A Supply Chain Management System

It’s vital to ask your EMS partner what they do to manage their supply chain and global manufacturing.

To run smoothly, they need to have a supply chain management system in place for any manufacturing process. With a system and vendors already in place, you won’t be scrambling to find parts in a pinch or be out of luck if one supplier stops carrying a component you need.

A well-known EMS partner with connections is ideal.

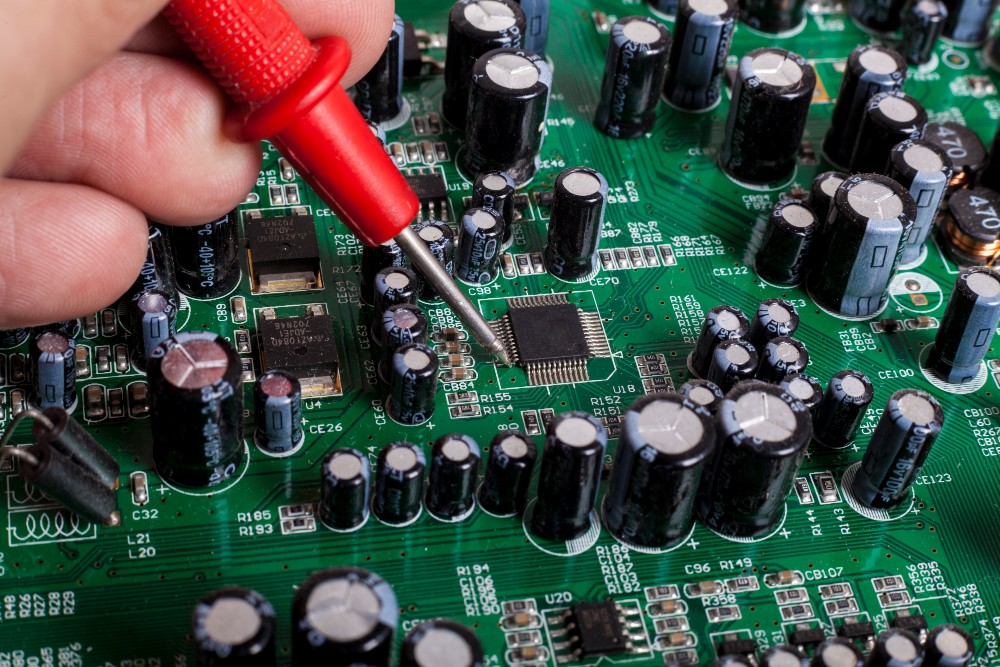

Product Testing

Just because production is complete doesn’t mean your product is ready for market.

In the testing stage, they should be checking for defects, board warping, too much solder, and other issues that may arise during production.

Catching any issues in the testing process before your product goes to market might cost you more in initial fixes and reproduction, but it will save your reputation and save you time in the long run.

Make Sure Your EMS Provider Meets Your Needs

With so many electronic manufacturing services options, it is difficult to choose the right one for your business.

As a reminder, take time to review your company’s highest needs. After determining your needs, start researching and interviewing EMS companies that can meet those requirements.