When you’re an engineer, you can be confident that you know your “stuff”—but since that can encompass many different things, it’s likely you’ll run into something you don’t know. Of course, that’s nothing to be ashamed about, especially if you’re straight out of school or haven’t been in the industry for long. The electronics manufacturing process, in particular, is complex.

Learning all the terminology can be daunting—so we are here to help. For starters, EMS (electronic manufacturing services) is a common term in the manufacturing industry. Let’s take a closer look at what it entails, the future of the industry, and what the right EMS partner can do for you.

What You Need to Know About Electronic Manufacturing Services

EMS refers to an industry, as well as a specific type of company or subcontractor. It can also be used interchangeably with the generic term “CM” (contract manufacturing).

EMS companies provide a variety of outsourcing services in engineering and manufacturing to original equipment manufacturers, which allow them to improve their operations and become more efficient. This way, businesses can focus more on research and development tasks.

The market for electronic manufacturing services is dynamic, and has seen monumental growth due to the continuous demand for electronic components. Of course, that growth won’t slow down anytime soon in the digital age.

To offset and keep up with this demand, outsourced electronic manufacturing services are also growing. In fact, experts say the industry is predicted to scale at a compound annual growth rate of 7.5% at least through 2024. To capitalize on the trend and keep costs down, many manufacturers choose to outsource to companies that offer expertise in this area.

The Future of Electronics and Manufacturing

The United States and China are the largest consumers of electronic products. We are filled to the brim with electronic devices—from computers and video games to smartwatches and mobile phones—all of which continue to increase in popularity. There is a rising demand for smart devices, artificial intelligence, and even self-driving cars.

The Consumer Technology Association expected consumer technology retail revenue in the U.S. to reach $422 billion in 2020—a staggering 4% year-over-year growth compared with the previous year alone.

What Can an Electronic Manufacturing Services Company Do for You?

It varies by the partner, but most EMS companies should be able to do all (or at least most) of these services:

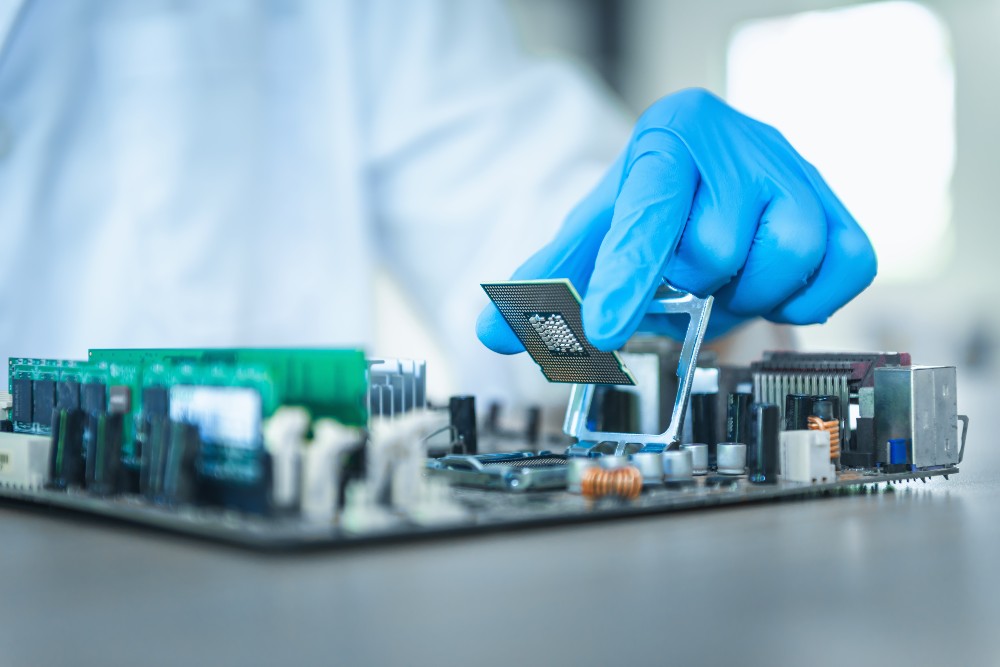

- PCB assembly – This refers to the assembly process involved in printed circuit board manufacturing, the heart of nearly any electrical appliance. Your new tech won’t run without PCBs.

- Cable assembly – Cables are critical to many different types of electronic products. They connect important parts to one another or to a power source, so their importance should never be overlooked.

- Electromechanical assembly – Getting this part right is imperative. If you want your products to work well and garner your company a good reputation with return customers, then you must pay attention to electromechanics.

- Contract design – An outsourced professional that deals with electronic manufacturing services should know how to create a sound contract that will help you grow relationships with the right business partners and protect your brand.

- Testing – Everything your facility manufactures should be tested to ensure the utmost quality. Most people are familiar with the concept, but it’s particularly crucial in this niche. You have to know you’re making the best product for the least amount of money—otherwise, you might have angry customers or clients to deal with down the road.

- Prototyping – This development stage ensures you have a feasible product that holds together and works as intended. Prototyping will give you the tools to make your device better and more advanced.

- Aftermarket services – These services can help you preserve your equipment and reduce—or completely eliminate—unnecessary extra costs from expensive redesigns. The strategy of any good aftermarket manufacturing service company should be to keep your machines running as long as possible.

Working With an Electronic Manufacturing Services Company

The electronics industry is continuing to grow at an impressive rate each and every day. As you start designing, assembling, and producing electronic products, partnering with an electronic manufacturing services company can help streamline your process. You’ll save time, money, and energy. You might even increase employee morale and customer satisfaction over time, so it’s definitely something to consider at your place of work.