In the electronics manufacturing world, there are so many acronyms to keep track of — but we’re here to help.

Surface-mount technology (SMT) is a staple term in the electronics manufacturing technology (EMT) industry. SMT is a modern and efficient process used in electronics assembly.

Traditionally, electronics were assembled using through-hole technology (THT) mounting. THT involves drilling holes into printed circuit boards, inserting leads into these holes, and soldering them on the “backside” of the PCB. Though-hole mounting uses manual assembly or automated insertion mount machines … and it’s time-consuming.

With SMT, components are placed directly on the printed circuit board rather than using through-holes. In most cases, surface-mount technology has replaced through-hole techniques because the process costs less, it can be automated, it limits errors, and it speeds up electronics assembly operations.

Let’s dive into the early days of surface-mount technology, how it’s used today, and the benefits of using this process in electronics manufacturing.

How Surface-Mount Technology Was Born

The need for automation in PCB assembly began trending upwards in the 70s and 80s after traditional assembly processes like THT couldn’t keep up with the demand for electronic devices.

Traditional techniques weren’t able to keep up with demand because holes needed to be perfectly drilled in each board before assembly could begin. The process was time-consuming — PCB components were small and needed to be fitted closer together. Humans and technologies at the time couldn’t physically get the holes small enough or the components close enough together.

In the early days of electronics manufacturing, holes were often placed incorrectly, making it impossible to assemble the PCB. When THT is done manually or with rudimentary automation processes, there is a high chance of human error, and errors start a horrible ripple effect. Errors cause production halts, escalated costs, and late deliveries.

It was discovered that component leads weren’t needed to pass through the board. Components could simply be soldered directly to the board, resulting in fewer errors during the assembly process.

IBM is noted to be one of the pioneers in creating and popularizing surface-mount technology.

By the late 1990s, the majority of electronics were assembled using surface-mount technology. Fast forward three decades and SMT is still the most popular choice for electronic manufacturing.

Surface-Mount Technology Assembly Process

The first step in the SMT process is to decide where the components will be placed and how your PCB will function. Then, program machines to perform the tasks needed.

Next, apply soldering paste to your boards. Soldering paste is a glue used to hold SMT components together. Too much solder paste could result in short-circuits, but not enough will lead to poor connections or a fragile board.

Perform a solder paste inspection before the component placement. The earlier you catch an error, the easier it is to fix during the production process.

Many SMT machines come with automated inspections.

After placing solder, boards are ready for component placement. Each component is automatically selected, reviewed for arrangement, and placed by your surface-mount technology machine according to the programming.

The device is then moved to the “Pre-Reflow Automated Optical Inspection” section of the machine to ensure that all components are placed correctly on the board. Component type, value, and polarity are also tested here.

Next comes the reflow soldering to connect your components. The board needs to be at the perfect temperature to avoid errors. Too little heat will result in poor connectivity, while high temperatures could damage the PCB.

The last step in surface-mount technology assembly is testing your PCB to ensure the assembly is correct.

Advantages of SMT

There are many benefits of SMT for electronic manufacturers, designers, and engineers.

SMT allows for a smaller PCB design, which is in high demand. As electronics get smaller (like smartwatches and cell phones), electronic designers and manufacturers must keep up with these trends when creating new products.

Surface-mount technology is also faster to assemble — especially compared to through-hole assembly. SMT eliminates the need to drill holes in printed circuit boards, reducing the steps in the assembly process.

With SMT, components can be soldered on both sides of the board, maximizing space and resources. Having double-sided PCBs also decreases costs (for packing, materials, etc.) and increases efficiency.

SMT Devices

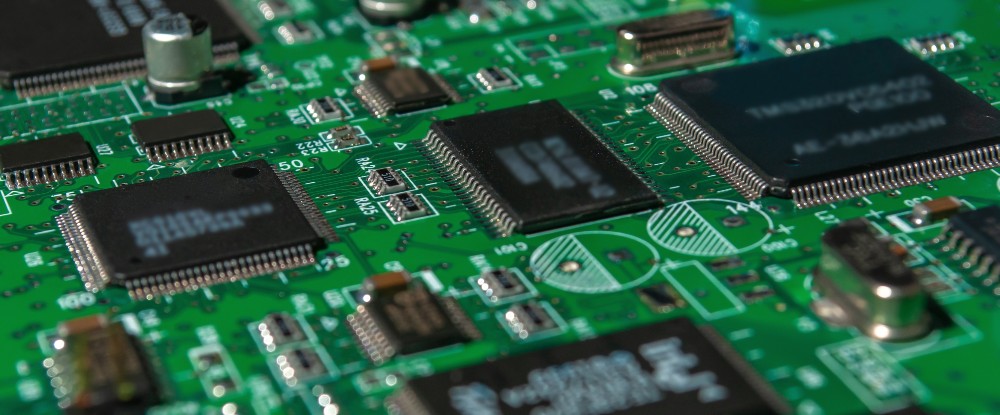

Surface-mount technology devices are categorized into three main categories: passive SMDs, transistors and diodes, and integrated circuits.

- Passive SMD: This is the primary surface-mount device (SMD). These are usually resistors and capacitors but also include coils and crystals. Other components for passive SMDs have more exclusive requirements that need their own packages.

- Transistors and diodes: Typically come in small plastic packaging. These types of SMDs always contain three leads, making it easier to determine where they must be placed.

- Integrated circuits: This is the most seldom-used SMD package. To determine if you need this package, determine the amount of interconnectivity required for your board. While most devices use less than 20 pins for connectivity, this package is for PCBs that require 200 or more pins.

Use Surface-Mount Technology for Your PCB Manufacturing

Surface mount technology has been the leading technique for printed board assembly since the 1990s. SMT can speed up the mass production of electronics while reducing the size, cost, and resources needed to manufacture them.

It’s possible to handle manufacturing on your own, but working with an EMS partner is one of the best ways to increase the efficiency of your electronic assembly process.